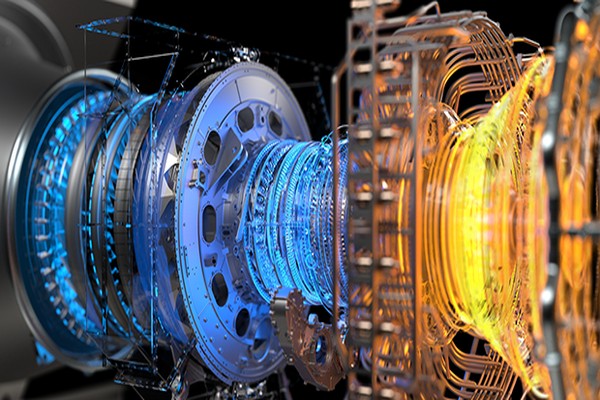

Existing steam and gas turbines come of age along with power companies. They want to achieve maximum unit lifetime, availability, and profitability.

Refurbishment and repair are becoming more and more typical activities. It’s for equipment maintained by both OEMs as well as independent restoration shops. Performance and dependability have typically been outstanding. This results in saving millions of dollars for particular applications due to avoided component replacement.

But the requirements of the cutthroat market never stop. Rim attachment cracking is a growing concern for low-pressure rotors. However, the Gas Turbine Repair Solutions to address serious issues don’t satisfy tight outage schedules.

The stresses brought on by high firing temperatures are often made worse by peaking operation. These are compressing hot-section component overhaul intervals. They’re requiring major maintenance earlier than expected for advanced GTs. Additionally, technology constraints and a limited vendor base can pose risks to the continued productive operation.

Integrated solutions for less costly, more efficient restoration of turbines are offered. It’s through advanced repair techniques and useful advice materials. They are currently under development by the EPRI.

Cracking

In fossil as well as nuclear power plants, fixing fractured turbine rotors along with disks presents several difficulties:

- To guarantee continuous operation throughout the remainder of the turbine’s life. The qualities of the repaired part must match or surpass those of the foundation disk material.

- Post-weld heat treatment or PWHT and weld solution cannot damage bolting or blading. Since this is still in the rotor, deform the disk or rotor, or impair the shrink fit.

- New blades with tolerances that are at least as excellent as those specified by the OEM. These must be machined into the repaired region.

Refining Cracking Resistance

To fix damage and enhance SCC resistance for aged and replacement disks. The mechanical shot peening procedures are being used more frequently. After grinding damaged disks to eliminate cracks, shot peening is performed. A cold-working procedure is carried out. Click https://inspenet.com/en/video-tv/top-5-ndt-innovation-technologies-2025/ to learn more about other innovative inspection techniques.

Small metal spheres, known as shot, are thrown at the component surface. These are creating tiny dimples by acting as miniature peening hammers. A zone of compressive tension is produced by overlapping dimples.

The efficacy of shot peening is still debatable despite its growing use. Some OEMs stated at an EPRI workshop that this approach can postpone the onset of further cracks. While others suggested that shot peening might potentially hasten the emergence of additional cracks.

Concerns center on whether the cold-finished surface is more prone to pitting. And whether a pit’s penetration of the comparatively shallow compressive tension layer increases susceptibility to SCC.

An emerging substitute for shot peening is laser shock peening, or LSP. To establish the tightly stressed area in component surfaces, laser-generated shock waves are used. The majority of LSP, as well as shot peening data, is confidential to OEMs and restoration suppliers.

Welding Technology

To achieve the precise requirements needed for high-performance and high-temperature operation. Hot-section components in new gas turbines are built using complex, high-strength alloys and superalloys.

The strains are placed on these materials by both peaking along baseload operation. Despite their fundamentally different nature. These put an emphasis on methods for economical component refurbishment as well as life extension.

The ability to prolong the operational lifespan of superalloy blades is limited by current welding technologies. Repairs are limited to the airfoil’s upper tip region. Damage in more heavily stressed locations may need costly and lengthy part replacement.

Repairing Specifications

- Cost-effective hot-section component restoration is becoming more and more important. Especially for large, older GTs to continue operating profitably. In a similar vein, parts of the more sophisticated F-class machines frequently need to be restored or replaced sooner than expected.

Independent service centers may provide more competitive prices. Together with technical expertise and physical capabilities on par with OEM facilities. To guarantee a high-quality, economical solution. EPRI tools offer recommendations for reducing hazards during the supplier selection process. Go to this page to read further.

- In December 2000, extensive repair and coating instructions for hot-section parts were released. These revised standards were created according to the 1992 guidelines. They are still widely used in the industry. Taking into account a great deal of feedback from turbine owners and operators, as well as maintenance providers.

They use cutting-edge methods for inspecting and evaluating damage. Especially in refurbishing nozzles, blades, combustion liners, and coatings for combustor transitions. This is to support competitive bidding processes, create purchase orders, and direct solution decisions.

- Additionally, more sophisticated machines and heated-section parts have comprehensive repair standards. For a refurbished piece to demonstrate a service life that is comparable to that of a new component.

The criteria include minimum requirements for heat treatment, weld repair, and other duties. They contain forms for dimensional examination, damage evaluation, and other processes. As well as technical, operations, and quality standards.

- In 2000, specifications were released for the repair of first- and second-stage nozzles. In addition to combustion liners and transition parts.

By using these requirements, power producers may make sure that the bids from various suppliers represent the same scope of work. Thus, enabling the price to be evaluated in relation to other crucial factors. This includes technical expertise, physical capabilities, preceding performance, and the completion schedule.